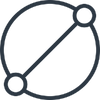

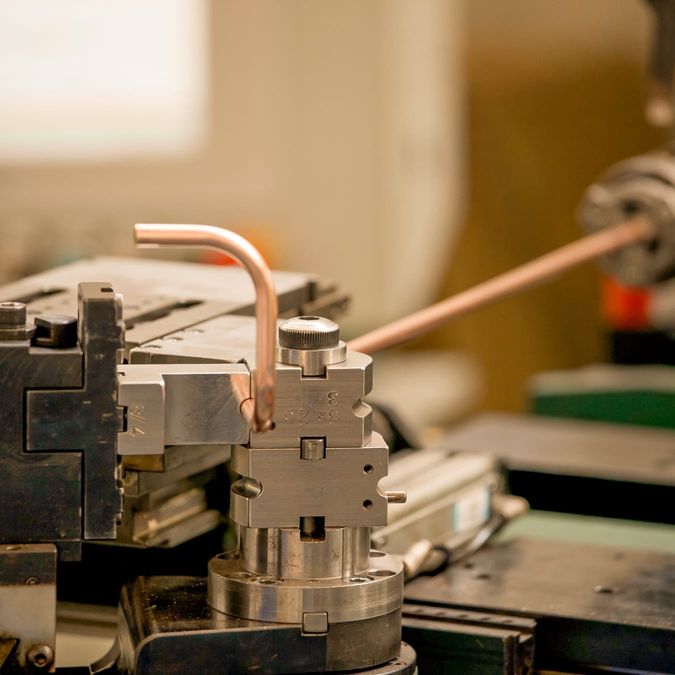

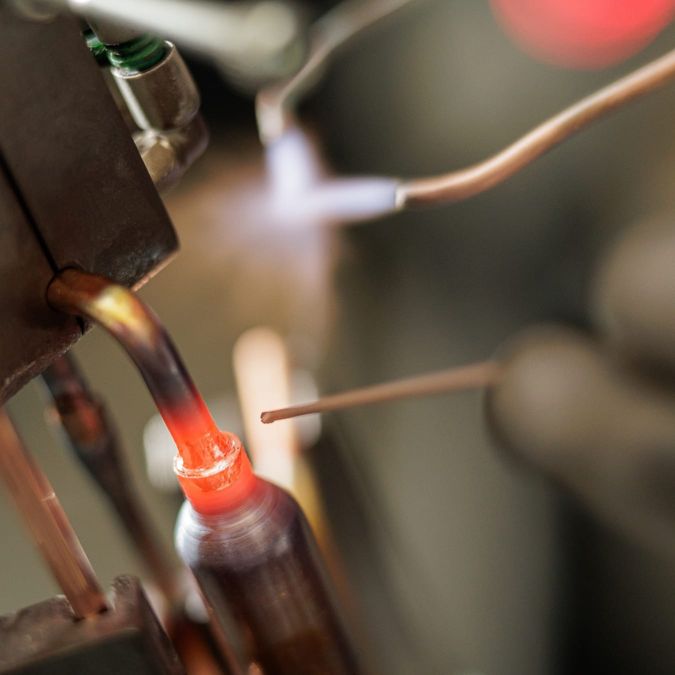

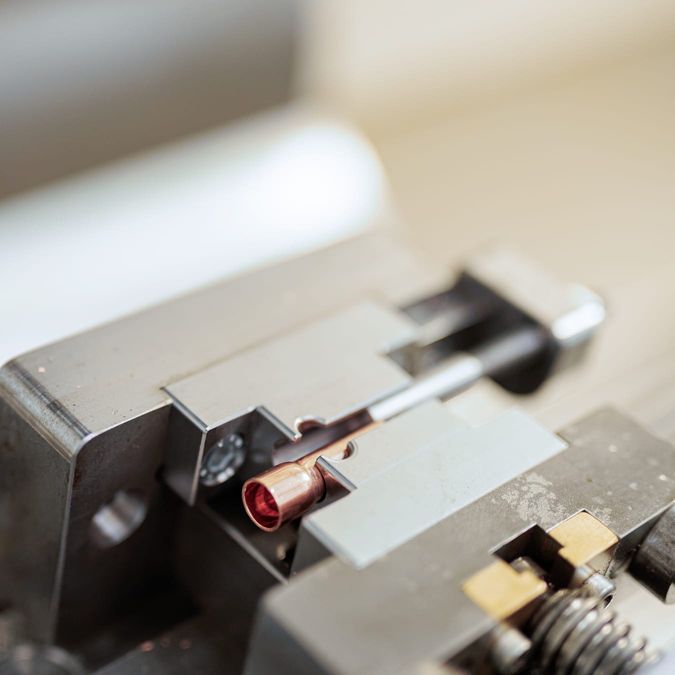

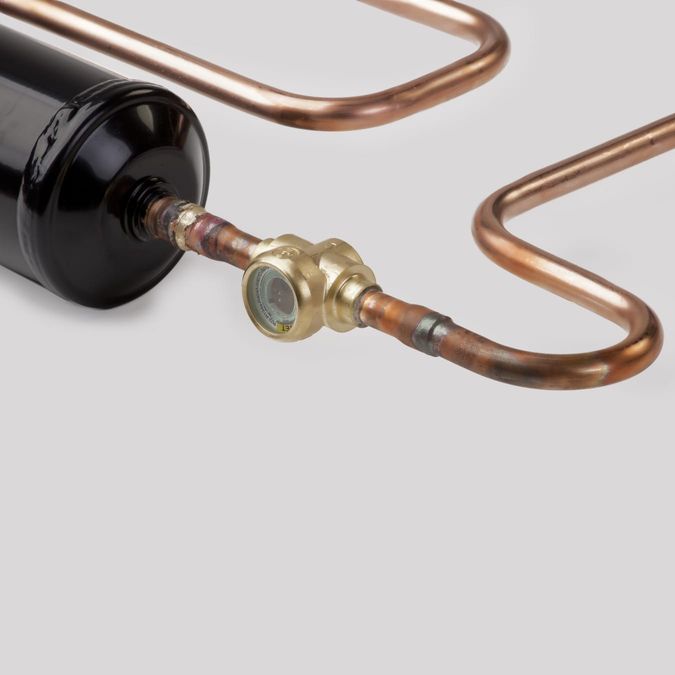

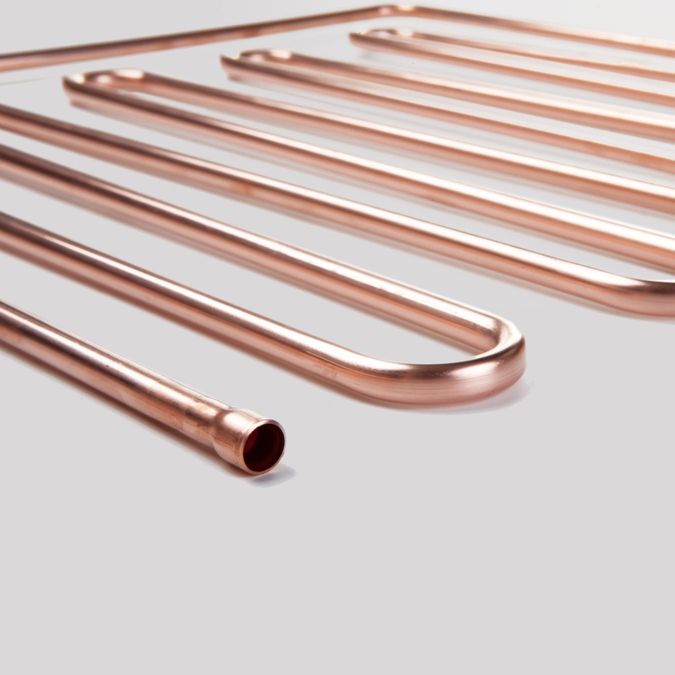

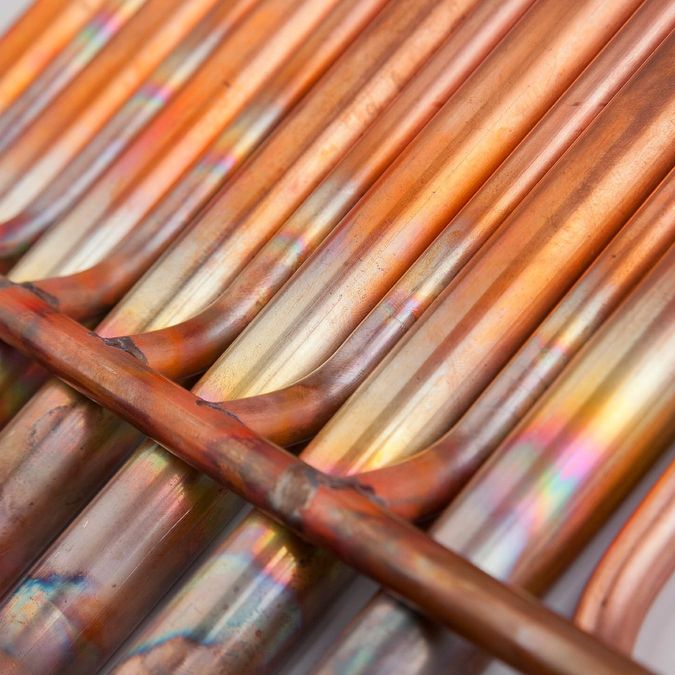

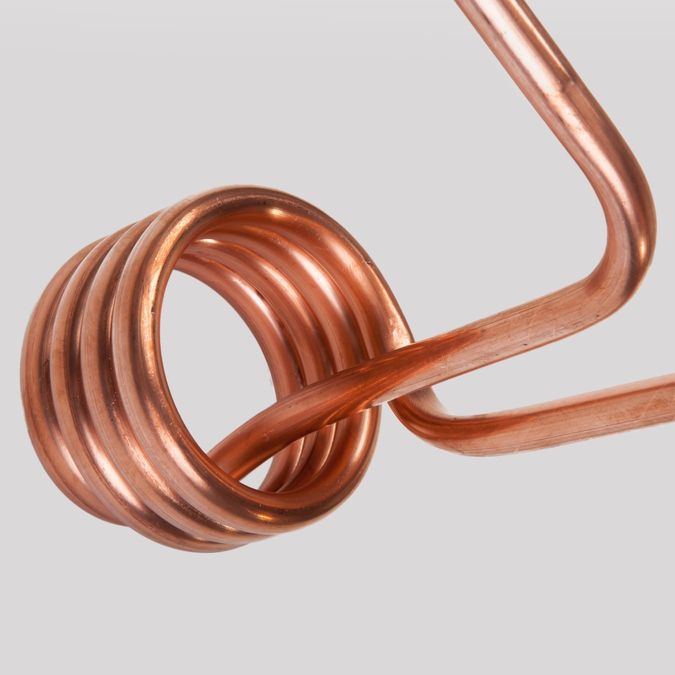

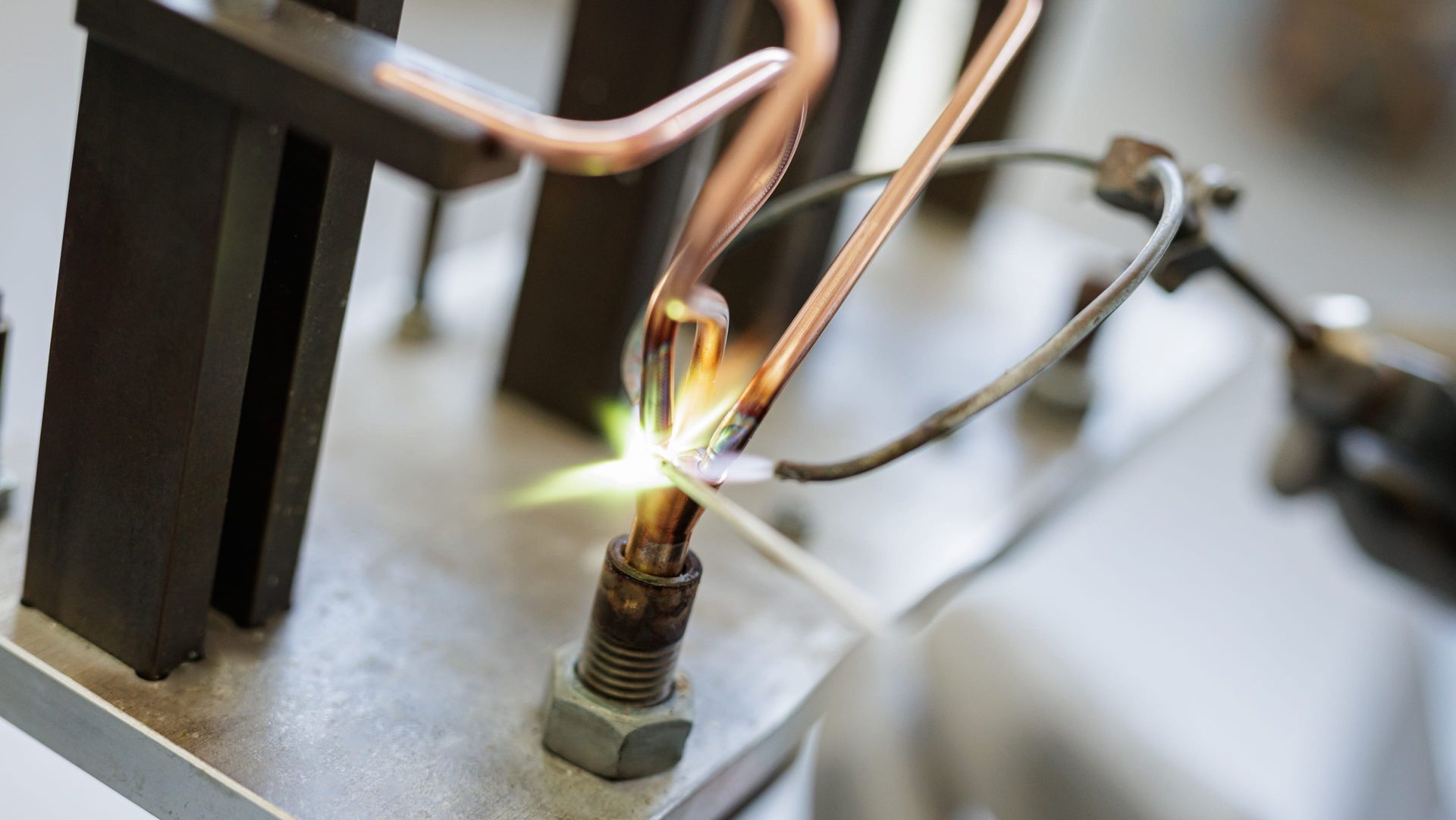

We curve, shape, braze and assemble copper tubes using brazing processes certified under UNI EN 13133:2002 with commercial components, employing custom-built templates and jigs. These assemblies can be supplied complete with insulation and/or sheathing.

We can also mount non-welded components such as sheet metal, electrical connectors and heating elements.

In addition to copper, we also fabricate tube assemblies using aluminium, iron and steel.

Tubes brazed or welded with commercial components, such as:

- Valves

- Filters

- Miscellaneous fittings

- Taps

- Charging connections

- Accumulators

- Pressure switches

- Indicators and gauges

- Anti vibration fittings