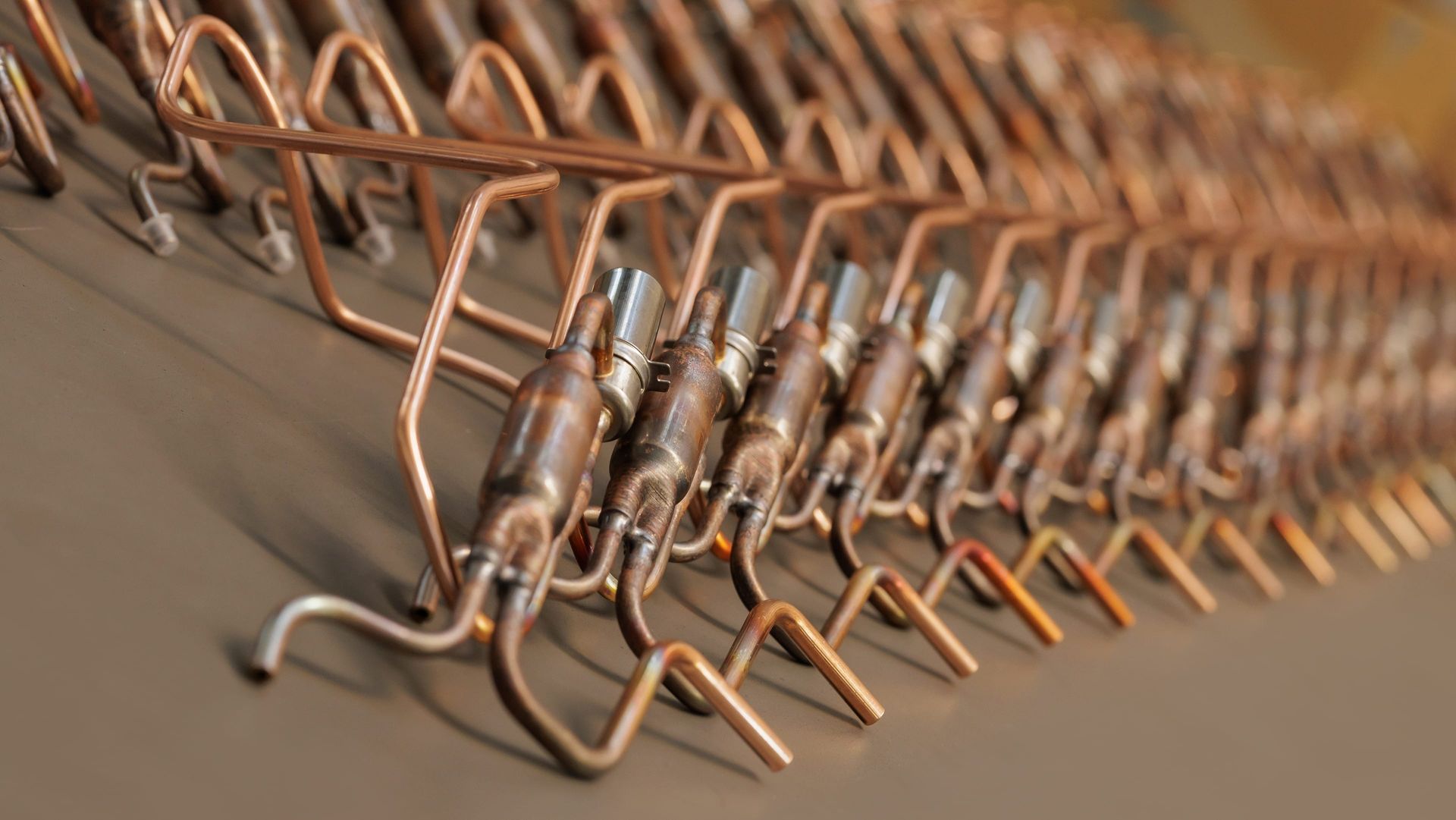

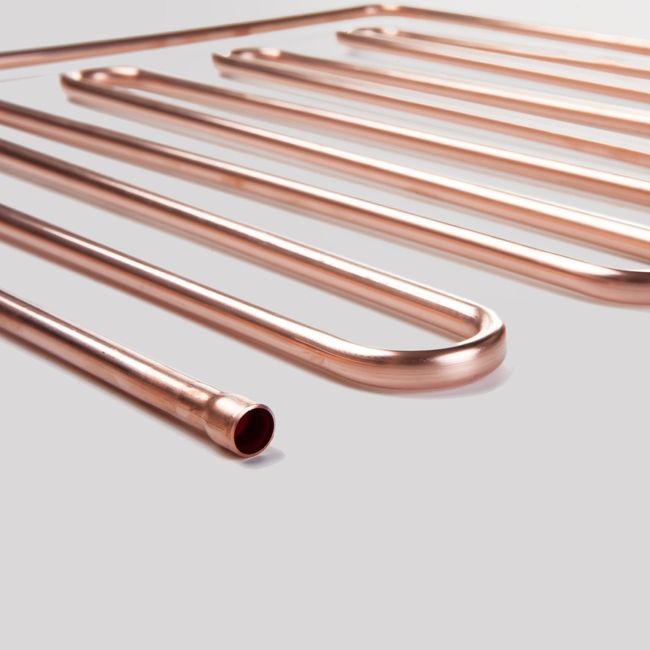

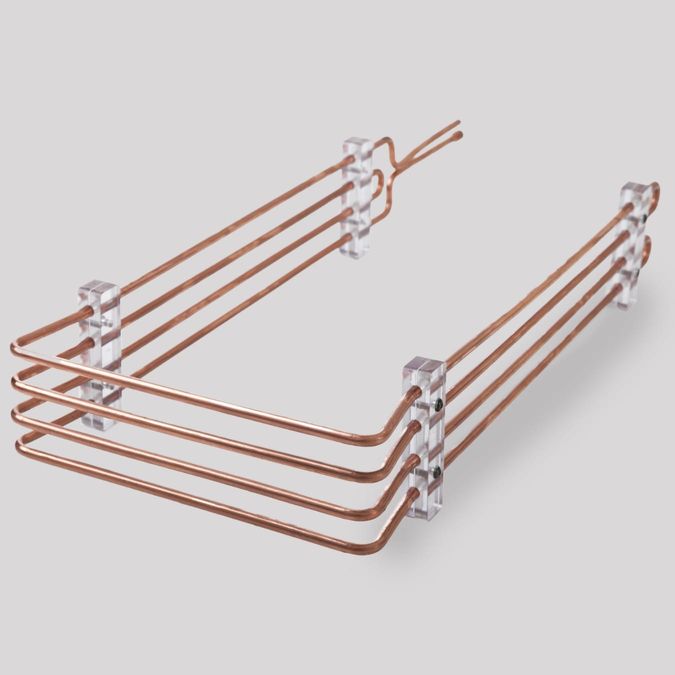

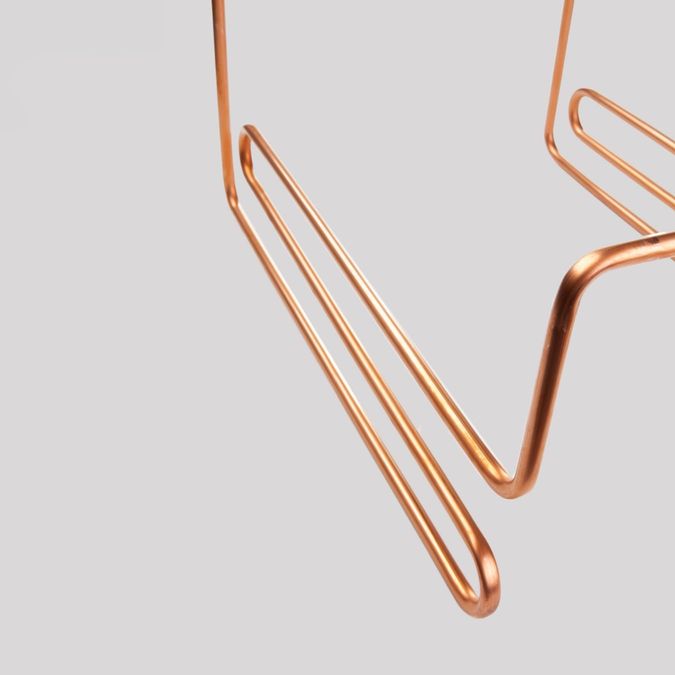

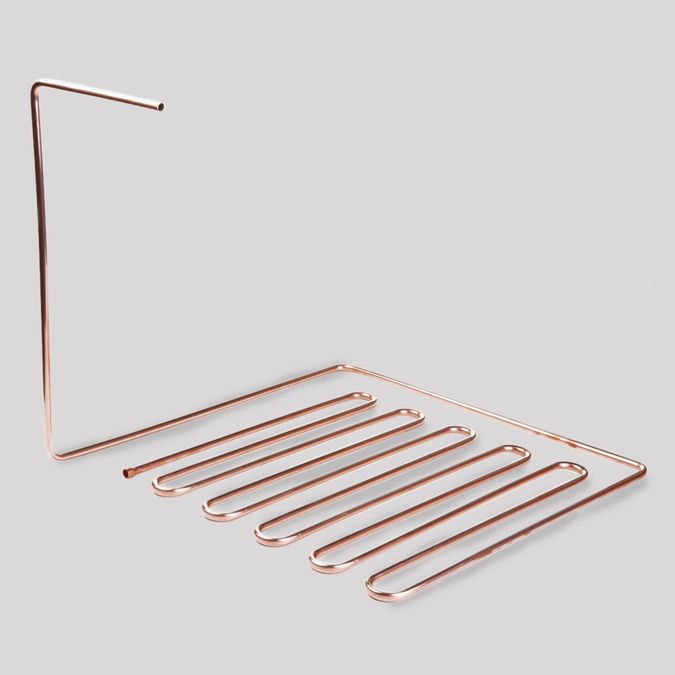

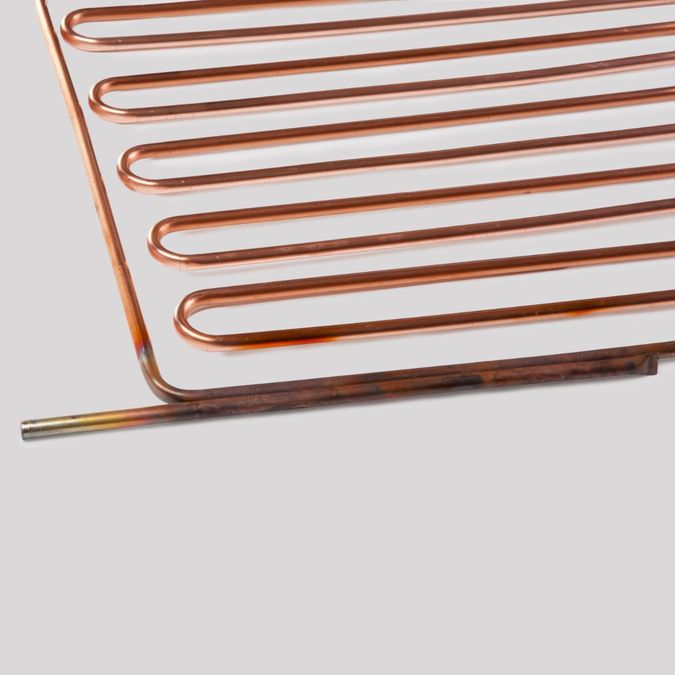

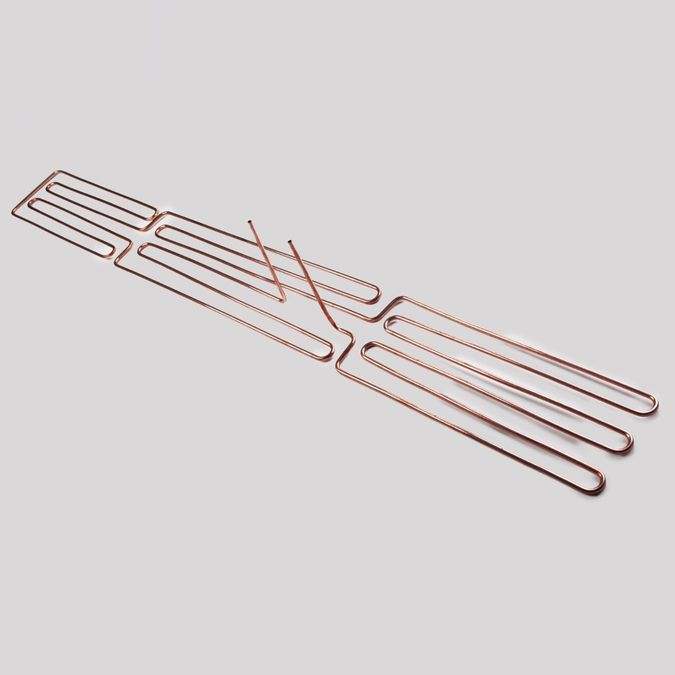

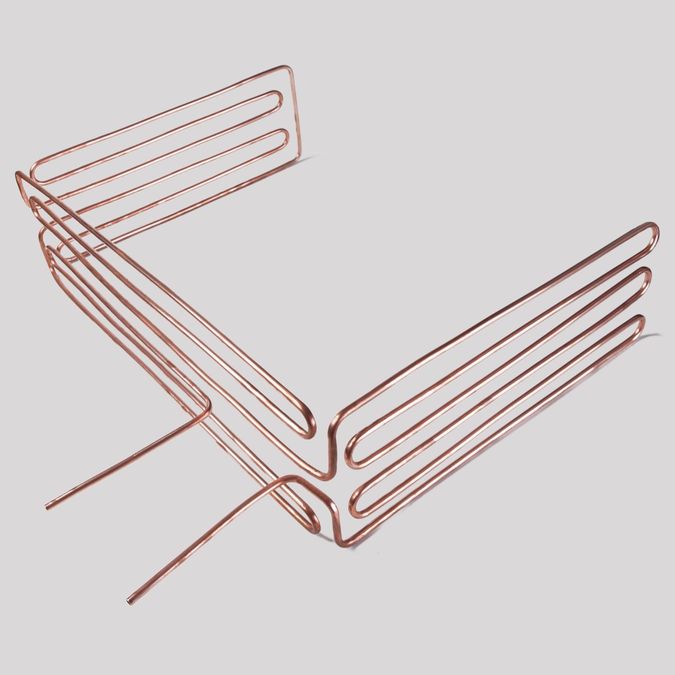

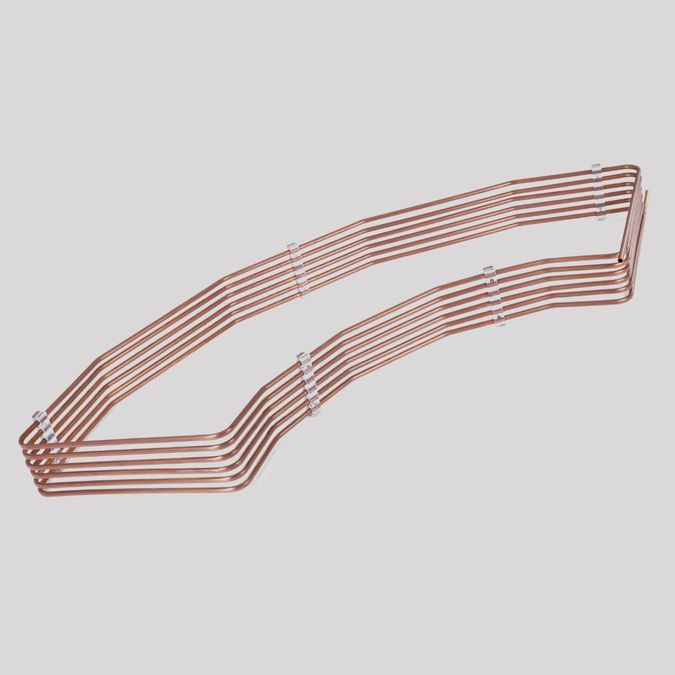

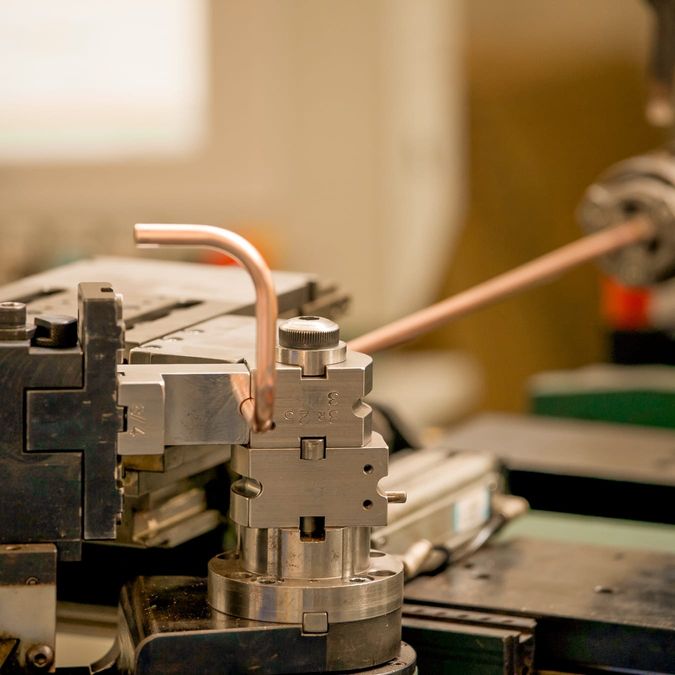

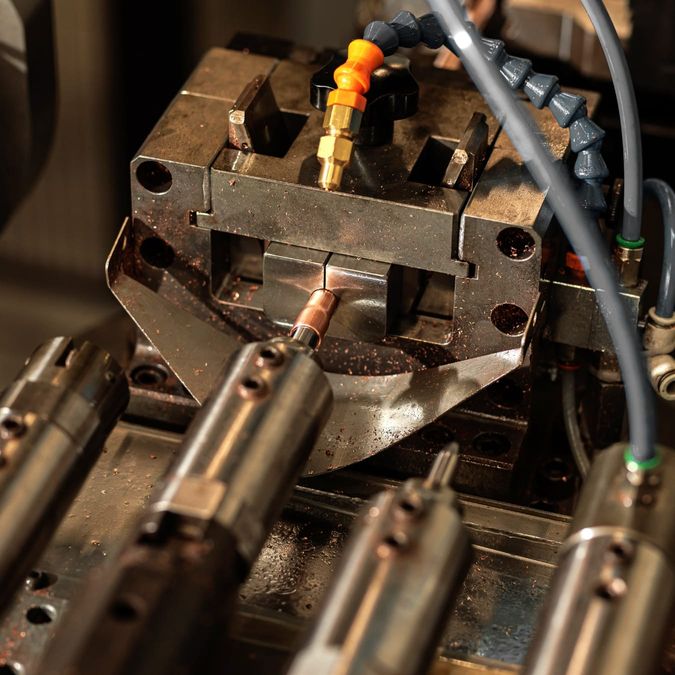

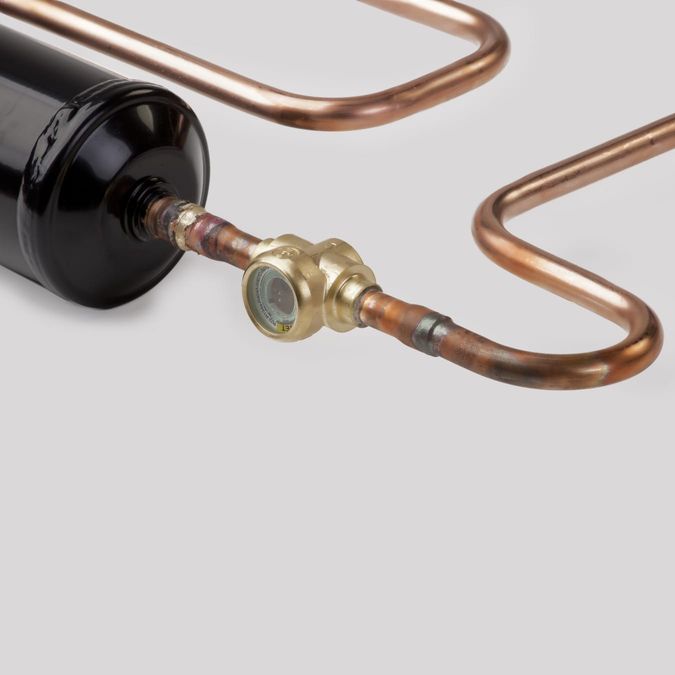

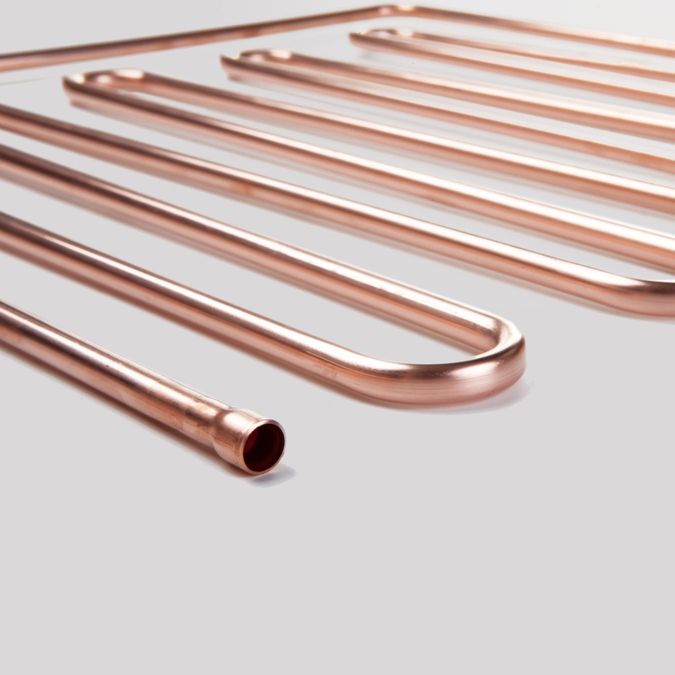

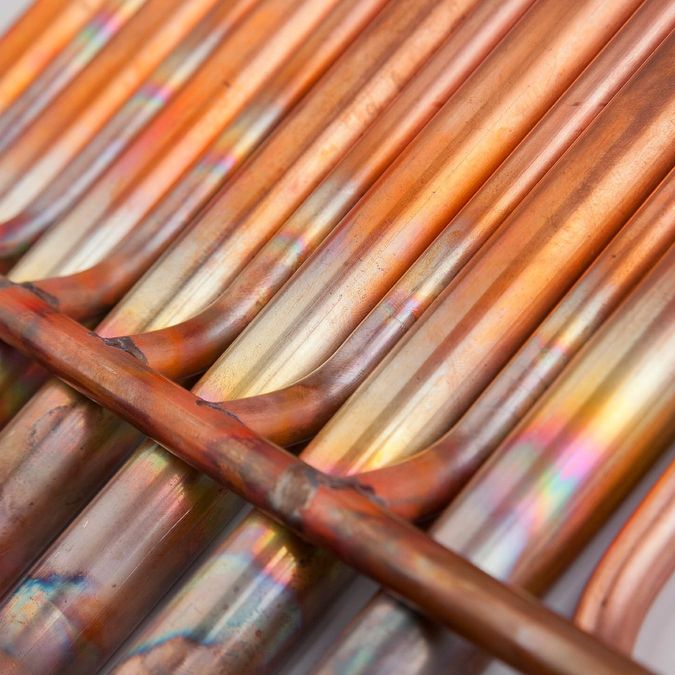

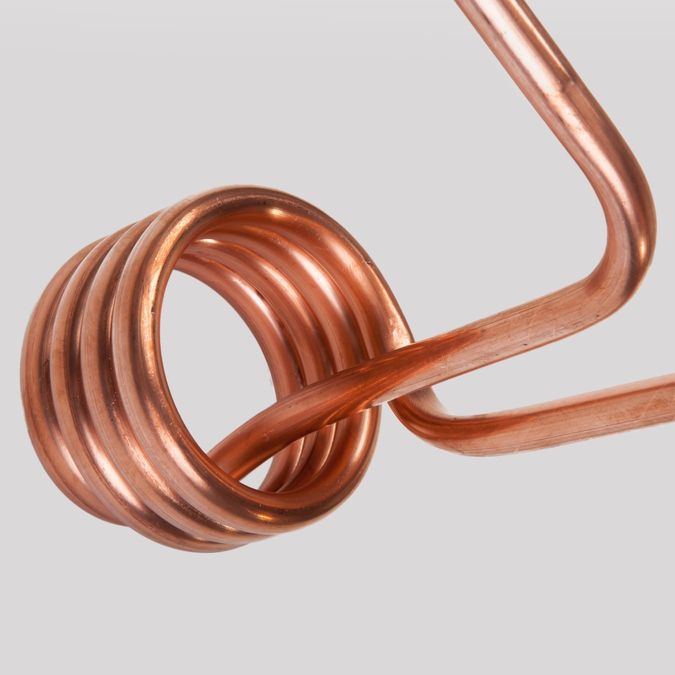

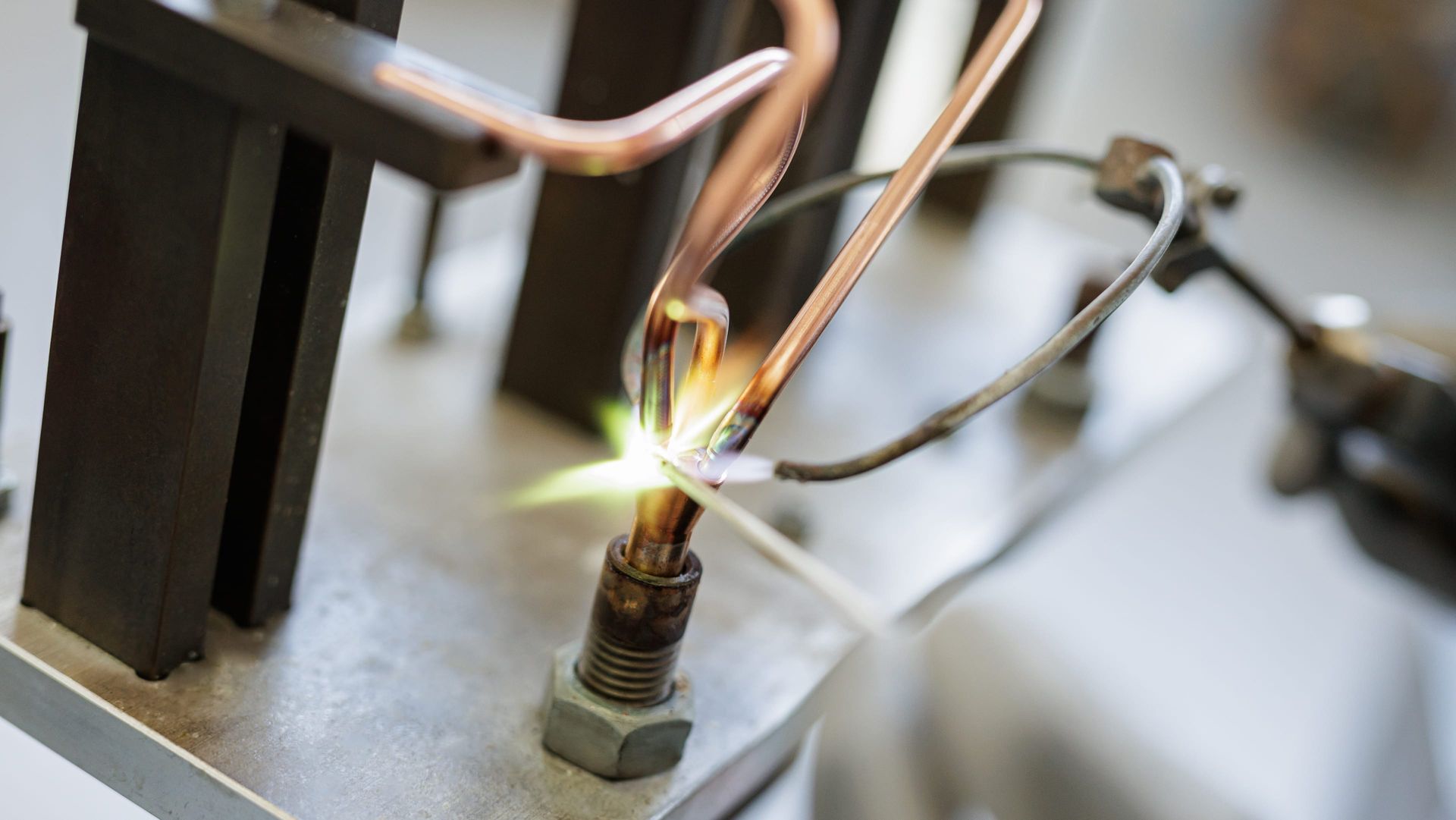

We are able to produce flat and 3D small and large coils, with tubing up to 14 mm in diameter and no length limit. Our flat and 3D copper coils are made to customer specification and developed using CNC machines. We can manufacture copper coils with formed ends and fitted with all required accessories. In addition to copper, we also produce flat and 3D coils using aluminium, iron and steel.

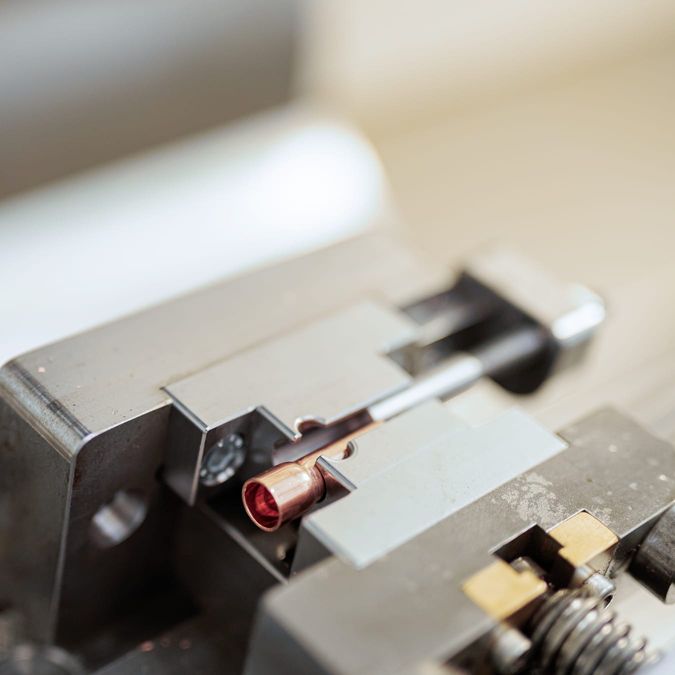

3D and flat copper coils with shaped ends, fitted with:

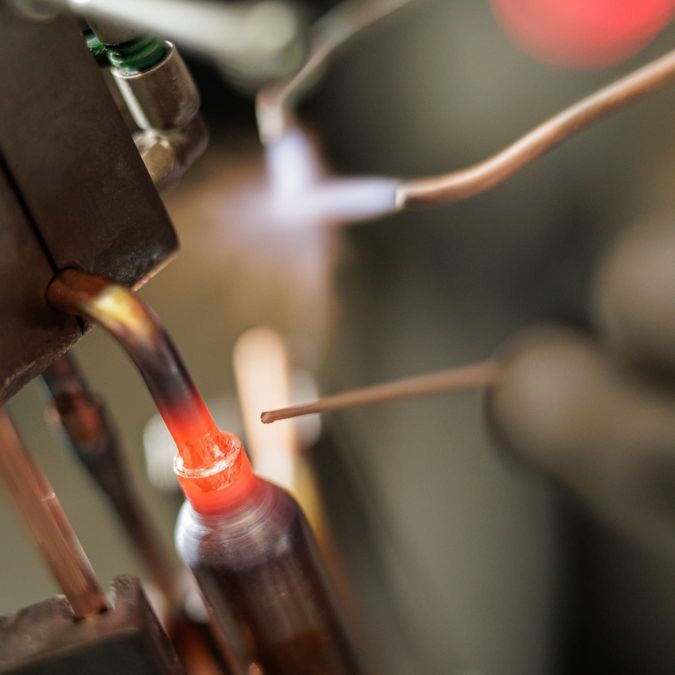

- Brazed and welded components

- Insulating sheathing

- Anti-vibration elements

- End fittings

- Supports, braces and spacers